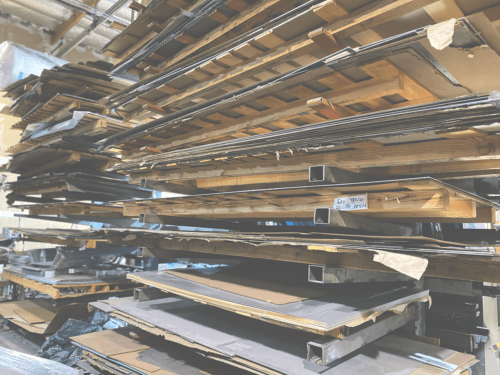

Tedco works with various types of metal alloys to manufacture parts. Here are some of the common materials we use, different material properties, as well as the different material thicknesses we work with to fabricate sheet metal parts.

- A36 is a very common mild steel. It is much easier to form than CRS 1018 but more difficult to machine.

- A653 Galvanized is a steel that contains zinc coating for protection against corrosion.

Stainless Steel (CRES) is an alloy based on chromium and steel and is categorized by its resistance to corrosion. The gauge thickness is the same as regular steel. Stainless is much harder than regular steel and is not easy to work with in some respects. Our lasers love it and have no problem cutting it. However, it is difficult to punch and can be difficult to weld. Below gives a description of the different stainless types:

- CRES 304 is the most widely used multipurpose stainless steel which is easy to weld and form.

- CRES 301 is commonly used for fasteners and springs which offers better wear resistance and fatigue than 304. This type has good weldability.

- CRES 316 has great corrosion resistance compared to 304, so it is best used for chemical processing applications. This type has good weldability and temperature resistance.

- CRES 303 is a good material to machine, which makes it best used to create screw machine products. It is also good for corrosion resistance and temperature.

- CRES 410 is commonly used for fasteners, machine parts, and shafts since it can be heat treated for extra hardness and extra wear resistance.

Aluminum is mixture of aluminum with other metals, often with copper, zinc, manganese, silicon, or magnesium. There are too many alloys of aluminum to list. The number after the 4-digit code is the tensile strength or temper of the alloy that ranges from T0 to T6. T0 is soft, and T6 is fully hard. VIP uses, 5052-H32, 6061-T6, 6061-T4, 2024-T0 for most of our parts. Below gives a description of the different series of aluminum:

- 5052-H32 is the most common alloy we use. It has excellent corrosion resistance, easy to form, and is easier to weld. It is not heat treatable and nonmagnetic.

- 6061-T6 is a multipurpose aluminum with good strength, corrosion resistance, and machinability. It is heat treatable but nonmagnetic.

- 2024 has great strength compared to mild steel, but weighs a lot less and has less corrosion resistance than 7075. It is heat treatable but nonmagnetic.

- 7075 is a very strong and lightweight aluminum with better corrosion resistance than 2024. It is commonly used for aircraft parts which are where it gets its common name “aircraft aluminum.”

Sheet Metal Thicknesses

The most basic question is ‘What is sheet metal?’ Sheet metal is metal that has been formed into a sheet that is thinner than bar stock, but thicker than foil. Sheet metal can vary in thickness and types of metals. However, the most common thicknesses are less than ¼” thick. Generally, when a sheet of metal reaches a critical thickness and cannot be used on a turret punch, but rather a CNC machine, it is called a plate. Usually this includes sheets of metal that are 3/16″ or thicker. Plates are categorized by their thickness and labeled by it as well. Quarter inch steel hot rolled plate is just called, ¼” HRS (Hot Rolled Steel). Sheets of metal thinner than 3/16″ are categorized by thickness as well, but the actual thickness is converted into simpler numbers referred to as “gauges” for steel. Below are the conversions of gauges/ thicknesses for common sheet metal types:

| Steel / Stainless Steel | Aluminum | ||

|---|---|---|---|

| Gauge | Thickness | Gauge* | Thickness |

| 28 | 0.015” | 22 | 0.025” |

| 26 | 0.018” | 20 | 0.032” |

| 24 | 0.024” | 18 | 0.040” |

| 22 | 0.030” | 16 | 0.050” |

| 20 | 0.036” | 14 | 0.063” |

| 18 | 0.048” | 12 | 0.080” |

| 16 | 0.060” | 11 | 0.090” |

| 14 | 0.075” | 10 | 0.100” |

| 12 | 0.105” | 0.125” | |

| 11 | 0.120” | 0.160” | |

| 10 | 0.134” | 0.190” | |

| 8 | 0.160” | ||

| 7 | 0.1874” | ||

| 3/16” and thicker is plate | THERE IS NO OFFICIAL GAUGE STANDARD FOR ALUMINUM 0.250” and thicker is plate *American Wire Gauge | ||

Links to Commonly Used Sheet Metal Products

Pem Engineering & manufacturing: Manufacturers of PEM brand threaded inserts, standoffs, studs and more. www.pemnet.com

Southco: Manufacturers of access hardware, latches, hinges, and rivets. This site contains electronic CAD files that can be downloaded for use in designing your assemblies.

www.southco.com

Wilson Tool International: Manufacturers of standard and special application tooling for turret presses www.wilsontools.com.