Every project that comes through TEDCO starts with the Amada ENSIS Fiber Laser. Its efficiency is unmatched, and the rapid speed at which parts can be manufactured provides a competitive advantage for medical, aerospace, semiconductor, and agriculture industries—these industries, complex machinery and equipment, proving that time is of the essence.

Prototyping Capabilities

Fast prototyping in these sectors is crucial to producing equipment that rivals competitors, so the quick setups and high-speed capabilities of the ENSIS Aje Fiber Laser are beneficial for getting products to market first.

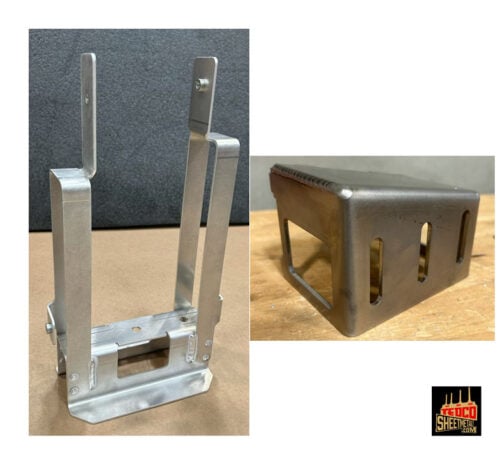

Examples of quick-turn prototypes that TEDCO has made using our Amada ENSIS Fiber Laser include components for an aluminum .125 structure for an energy company. For this project, revisions were made once before the perfect fit was found. A prototype that fulfilled our customer’s requirements on the first run was a stainless steel .135 conveyor adjustment bracket engineered by an agriculture facility for an existing machine. We always strive to meet our customers’ needs, when they requested the quickest turnaround possible, we did it in record time.

Bulk Production

After requesting a part priority list to ensure the needed items would be delivered quickly and the first off the assembly line, our shop got to work on production. This project involved over 75 electrical control boxes with lids made from .09 aluminum.

Specialized Materials

The Amada ENSIS Aje Fiber Laser can cut this material without damaging the outer ridges, keeping the aesthetics as the customer desires.

The fiber laser has consistently met the challenges of any project TEDCO has undertaken. We are optimistic that this machine will enhance production quality and cost efficiency for many years.

Request more information on our shop’s capabilities for your upcoming precision sheet metal fabrication projects.